Cast steel shot WS

Description

V Abrasive Cast Steel Shot is a hardened hypereutectoid steel shot. The structure of the shot is tempered, fine-grained and homogeneous martensite, which provides optimum specific impact strength and fatigue strength. This type of shot is used when it is necessary to achieve the effect of mass and maximum rebound to clean the surface, as well as to harden the surface (work hardening).

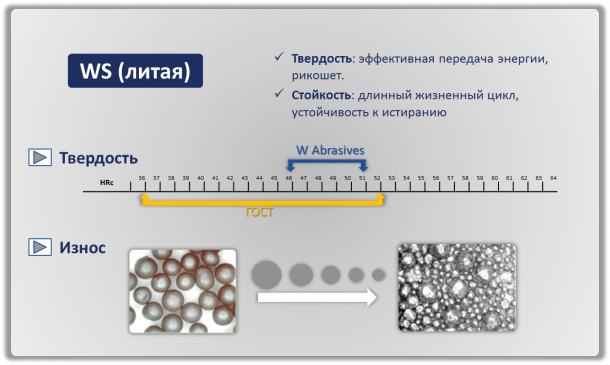

WS - Cast shot (hardness 45-51 HRC)

WS is the most universal in application, gives a roughness with smoothed peaks (troughs of a hemispherical shape). When processed with WS cast shot, the surface profile is characterized by smoothed peaks, the surface roughness after processing is characterized by a minimum depth (Rz) and the number of peaks (Pc) per centimeter. It has a maximum life cycle (see graph) due to its high resistance to abrasion and is effective in machining parts with hard-to-reach cavities due to the ricochet phenomenon.

Cast shot is used in shot blasting equipment in the following processes:

- cleaning of castings and cast billets from molding sands (steel and iron castings, copper and aluminum alloys);

- descaling (forgings, stampings, parts after heat treatment);

- surface hardening - hardening (springs / springs, shafts / rods; cast steel shot WS of special hardness 52-57 or 57-61 HRC is available for this process);

- cleaning and surface preparation before coating;

In the working mixture, it retains a mostly spherical shape.

The main characteristics of this fraction are:

- optimal hardness, allowing fast and high-quality processing,

- toughness for exceptionally long shot life,

- resilience that improves efficiency by providing multiple bounces to reach areas that cannot be hit directly.

| Наименование изделия | Хим. состав | Средняя твердость | Гранулометрический состав |

|---|---|---|---|

| Дробь стальная литая WS | Углерод 0,8-1,2%, Кремний 0,4-1,2%, Марганец 0,6-1,2%, Фосфор ≤ 0,05%, Сера ≤ 0,05% | 45,3 - 51,3 HRC Специальная 550-630 HV (52,3-56,8 HRC), 630-720 HV (56,8-61 HRC) | Согласно ТУ 4196-001-78730722-2010 |

| Минимальная истинная плотность измеряемая методом вытеснения спирта | Разброс по диаметру, мм | Микроструктура |

|---|---|---|

| ≥ 7,4 | 0,18-2,36 | полностью однородный и мелкозернистый мартенсит |

The size of the granules affects the quality and speed of processing. The greater the number of particles contained in a kilogram of the product, the higher the surface cleaning rate: per unit time, a greater number of shot granules interact with the surface being cleaned, but the shot must be of sufficient size to fulfill the technological task.

| Марка литой дроби | Номинальный размер, мм | Кол-во частиц в 1кг |

|---|---|---|

| WS 930 | 2,36 | 21.000 |

| WS 780 | 2,00 | 25.000 |

| WS 660 | 1,70 | 42.000 |

| WS 550 | 1,40 | 70.000 |

| WS 460 | 1,18 | 120.000 |

| WS 390 | 1,00 | 205.000 |

| WS 330 | 0,85 | 335.000 |

| WS 280 | 0,71 | 550.000 |

| WS 230 | 0,60 | 925.000 |

| WS 170 | 0,50 | 2.640.000 |

| WS 110 | 0,30 | 7.480.000 |

| WS 070 | 0,18 | 26.400.000 |

Five pros for the V Abrasive shot:

- Снижение расхода дроби за счет ее повышенной износостойкости

- Повышение срока службы быстроизнашиваемых деталей машин

- Повышение производительности, сокращение времени очистки и экономия электроэнергии.

- Снижение пылеобразования, уменьшение загрязнения обрабатываемых деталей и количества отходов.

High performance characteristics are determined by:

- careful chem. composition;

- metal structure: completely homogeneous and fine-grained martensite;

- narrow and stable variation in hardness and particle size distribution.

Vilabrator Allevar Ural presents its customers with an integrated approach, which includes, in addition to supplying a high-quality product, service technical support.

As part of a unified customer service system, a wide range of services is provided:

- advice on the selection of fractions in accordance with the technical requirements of the customer;

- instrumental control of the surface condition after processing;

- carrying out diagnostics of the work of shot-blasting, shot-blasting equipment, analysis of the current state, a program for the reconstruction of equipment to increase efficiency and practical assistance in its implementation;

- training of the customer's personnel in the methods of economical and efficient operation of the equipment.