Garnetiferous sand for waterjet cutting

Garnetiferous sand is a non-metallic natural mineral, composed of Almandine garnet granules, is an extremely hard and heavy abrasive with a density of about 4.1-4.3 g / cm3. Garnetiferous sand is not carcinogenic and non-toxic, however, being a natural mineral.

Cubic garnet crystals have an angularly-rounded granulation form. Due to the high hardness (7-8 Mohs) associated with their crystalline structure, high resistance to destruction is provided. Therefore, garnetiferous sand of different fractions is used as an abrasive in many industries.

Mountain garnet due to crushing from large rocks allows you to get any fraction size. Large fractions of 0.4-1.2 mm are especially appreciated for sandblasting and water treatment. The presence of sharp edges obtained after the split of the rock makes it more effective in water-abrasive cutting and allows you to get a more even cut surface.

The most important characteristic that determines the physical qualities of a mineral is its origin, its morphology, and its age. The morphology of garnets is influenced by the environment of formation of the mineral, this determines its density, its chemical composition, its color.

Due to its origin, it is more resistant to destruction, which makes it easier to use for recovery after the first (and second, and third) use. It has almost no microcracks, unlike sand obtained by crushing, which allows each individual grain of sand to maintain momentum during the destruction of the material being cut during abrasive blasting.

Uralgrit produces 80 mesh sand - a powder for waterjet cutting of hard, brittle, metallic and non-metallic materials.

The sand for waterjet cutting of the Uralgrit company is made of granulated slag of copper smelting production (copper slag) and is a dark colored particle, acute-angled in shape with a hardness of at least 6 on the Moss scale. The fractional composition of the powder can range from 0.01 to 0.5. By agreement with the consumer, the composition can be made in any specified interval, which allows to provide the most suitable cutting ability for working with a specific material.

Technical characteristics and features of garnetiferous sand

| Moss hardness | from 5.5 to 7.5 |

| Fractional composition: | from 0.01 to 0.5 By agreement with the customer can be made in any specified interval. |

| Cutting jet diameter: | from 0.5 to 1.5 mm |

| Range of processed thickness | from 0.1 to 300 mm and above |

Sand application for waterjet cutting

Sand for waterjet cutting shows excellent cutting ability while working with a variety of materials on various equipment, both imported and russian.

Waterjet allows you to work with the following materials:

Metals (non-ferrous, ferrous, alloys);

Different types of stone: granite, marble;

Plastic;

Glass;

Rubber, unvulcanized rubber, etc.

Why exactly sand "Uralgrit" 80 MESH?

Firstly, in terms of quality, characteristics and methods of application, the Uralgrit waterjet 80 mesh based copper slag is not inferior to either garnetiferous sand (imported from India or Australia) or electrocorundum.

Secondly, the price of the Uralgrit waterjet 80 mesh is more attractive than that of Indian / Australian garnetiferous sand or electrocorundum.

As they say, if you can’t see the difference - why pay more?

Video of testing the Uralgrit waterjet:

| Fractional composition from 0.01 to 0.5. At the customer's request it can be made in any specified interval. |

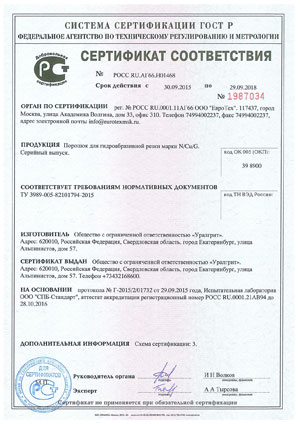

Uralgrit provides the following documents for sand for waterjet cutting:

- Certificate of Conformity in the GOST R system,

- Material Safety Data Sheet,

- Expert opinion on the conformity of products with the Unified Sanitary and Epidemiological and Hygienic Requirements,

- A quality certificate is issued for each batch/